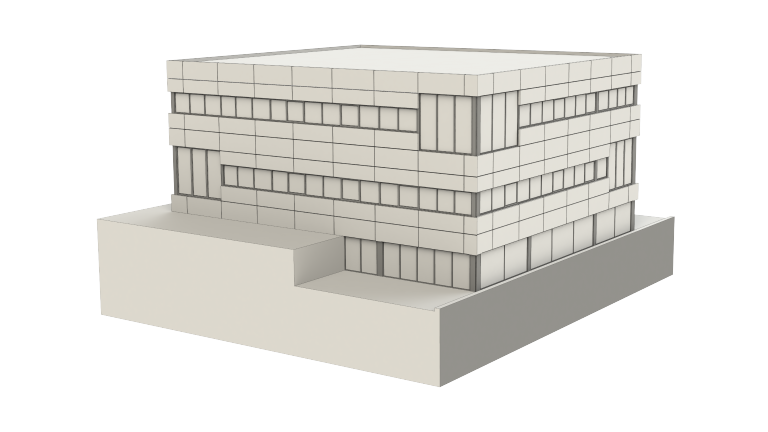

COFAC - SC

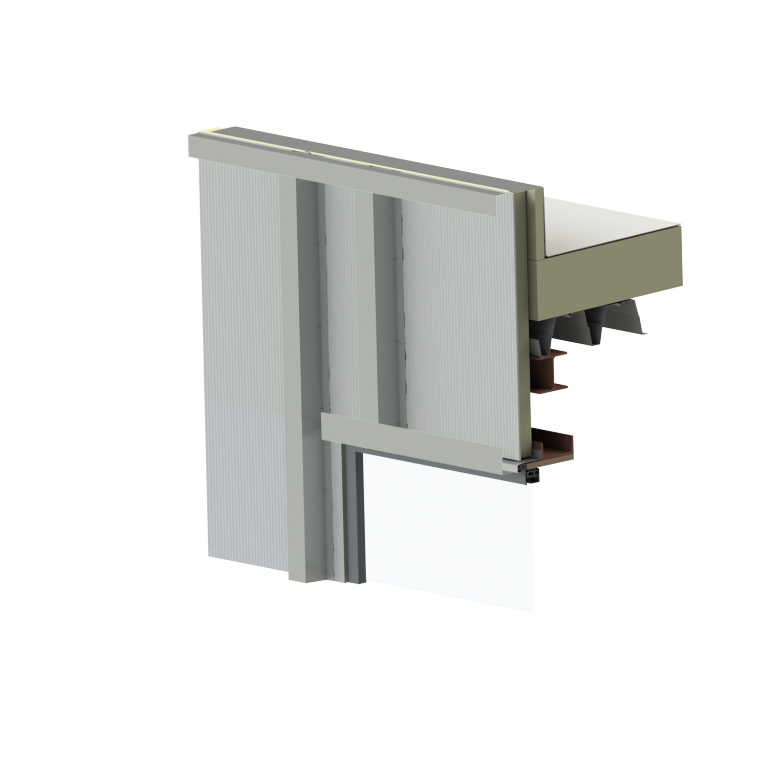

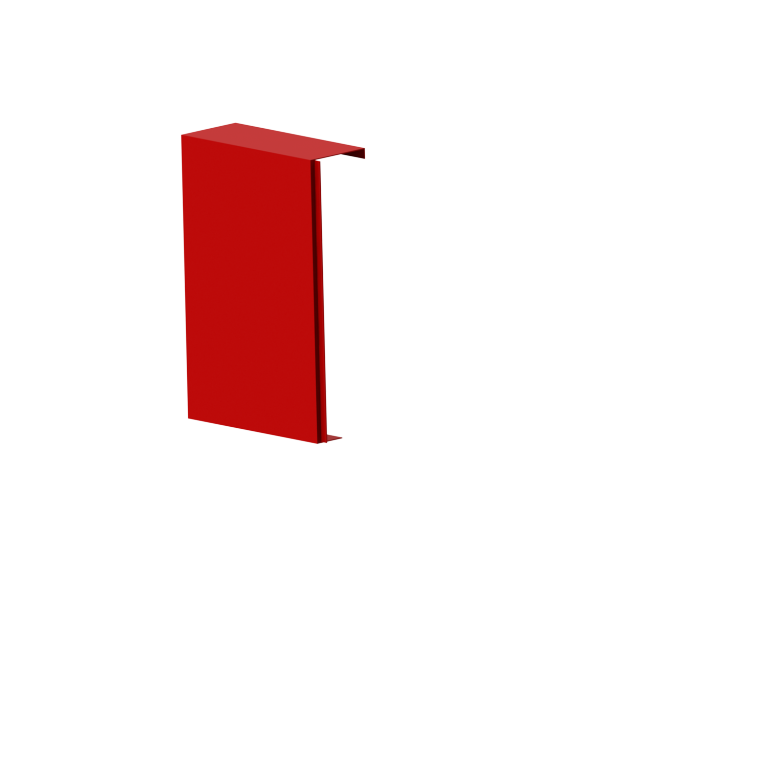

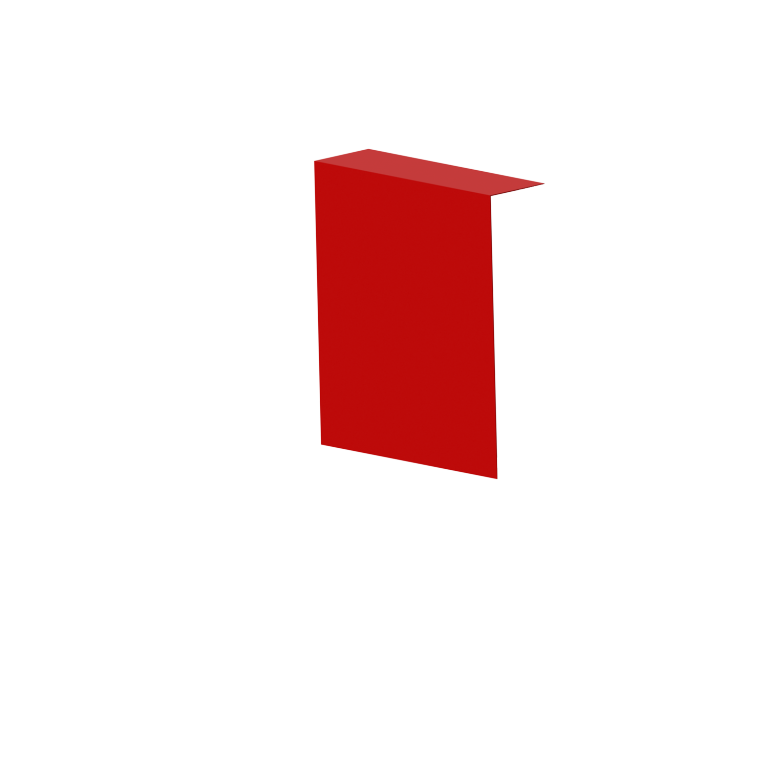

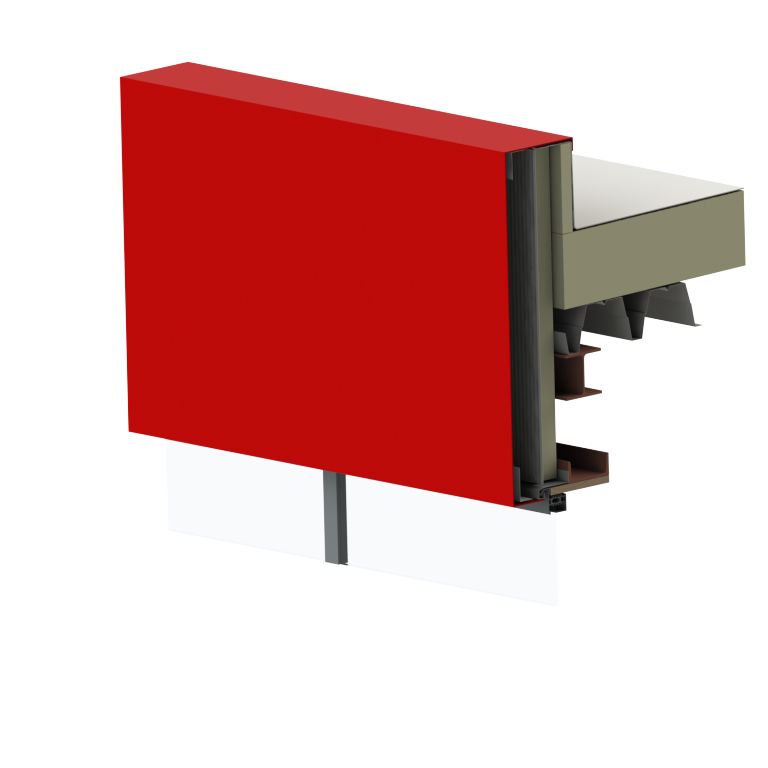

Screwed tray panel

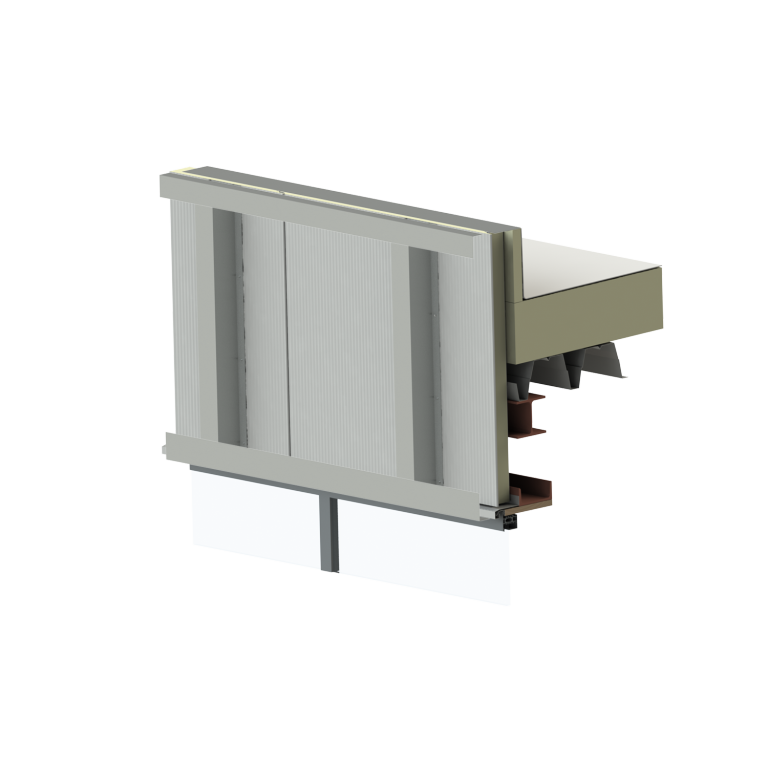

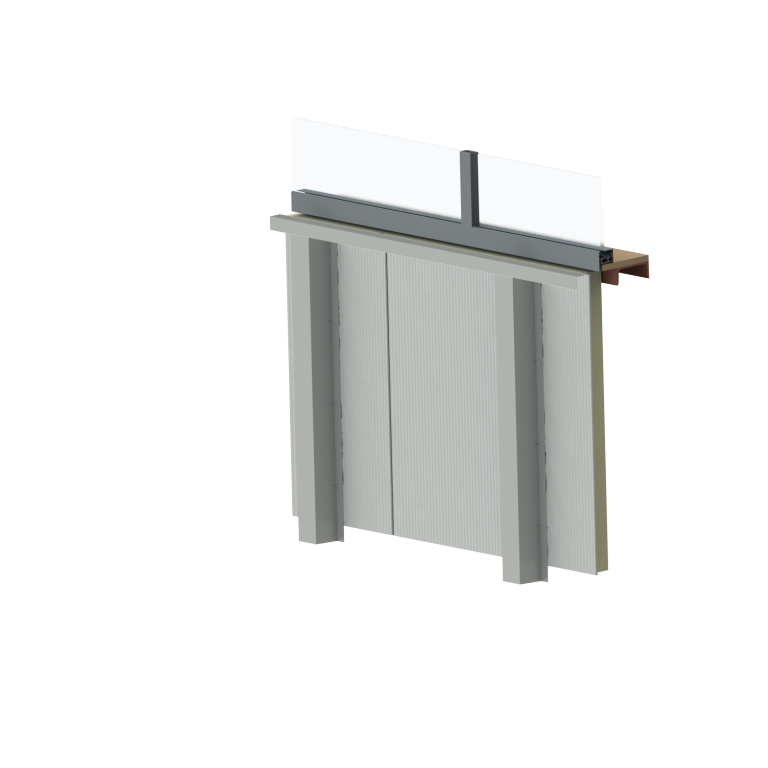

Our screwed tray panel is made from aluminium composite (thickness: 4 to 8 mm).

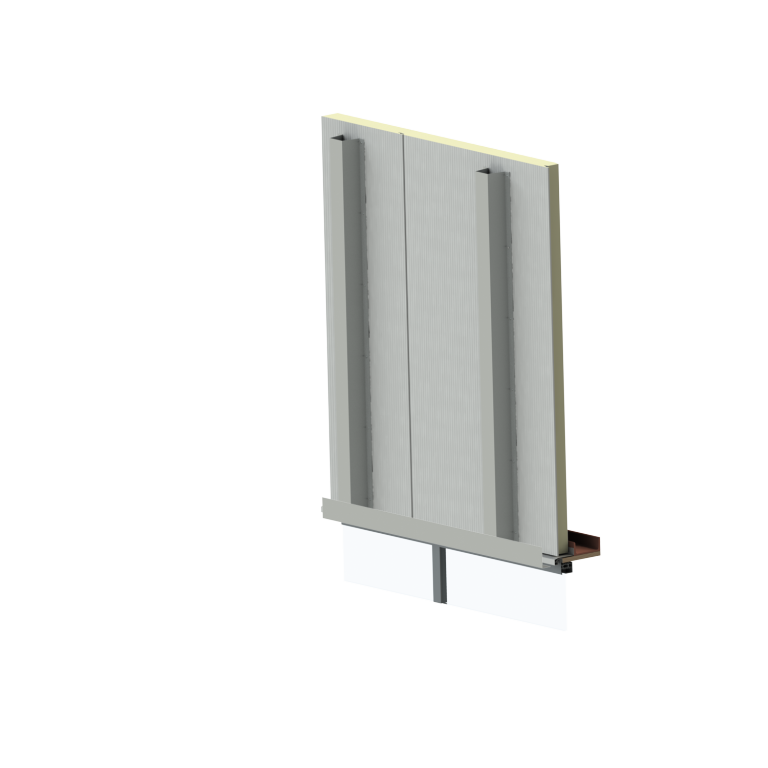

Sides are folded into a Z-profile during the production process. This gives depth to the screwed tray panel and creates a mounting bracket. The panels are bolted directly into the supporting structure via the bracket.

The bolt is visible in the joint in this type of cassette.

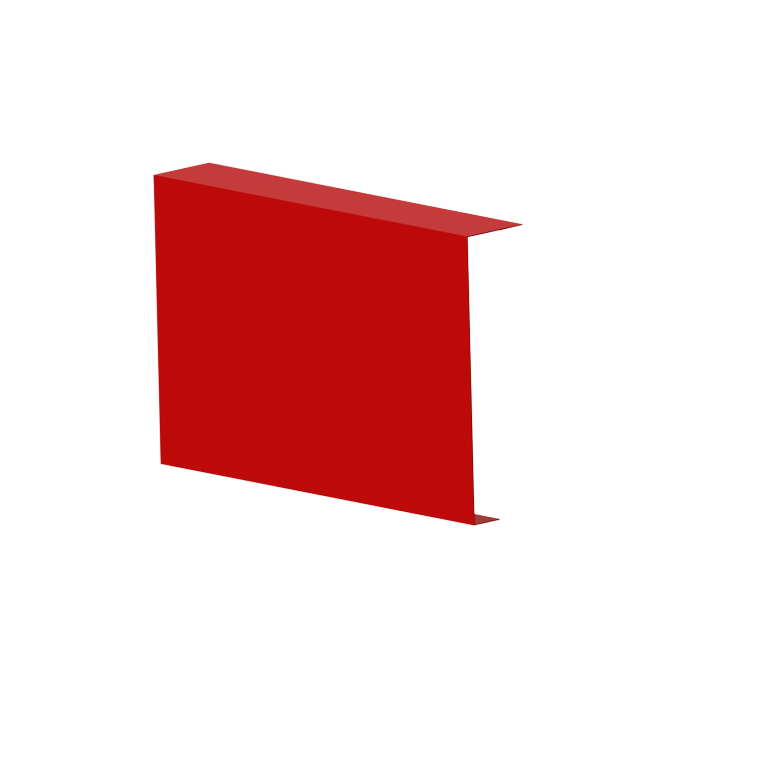

We always have various colours in stock. See our colour list for an overview.

We can supply any colour for orders of 250 m² or more. Our panels are available in standard widths of 1250 and 1500 mm and a standard length of 2000-8000 mm.

projects

View our most recent projects with screwed tray panels

To us, every project is a new challenge. We never shy away from challenges and always deliver customised solutions for optimal results.

The possibilities are endless with composite. Are you wondering if it’s the way forward for your project?

Take a look at our past projects for an idea of what’s possible.